Kaizen philosophy

The implementation of the Kaizen philosophy has had a profound impact on our company, fostering a culture of continuous improvement and driving positive change across all aspects of our organization by promoting employee engagement and empowerment.

The Hoshin Kanri is a strategic planning and execution method that aligns our company’s goals and objectives with the actions and initiatives of each individual. It provides a systematic framework for setting clear targets, defining key performance indicators (KPIs), and establishing a roadmap for achieving strategic objectives.

Our push in R&D

Our grinding company is deeply committed to research and development: we recognize that innovation drives progress, and by exploring new technologies and refining grinding techniques, we strive to remain at the forefront of the industry.

Through this unwavering commitment, we have successfully secured numerous patents: these patents not only showcase our expertise and leadership but also provide a solid foundation for future growth and differentiation in the market.

Our patents

Universal thrufeed loading system

Automatic blade height adjustment

A.I. Algorithm for improved grinding

New integrated electrical cabinet design

New brake discs grinding technology

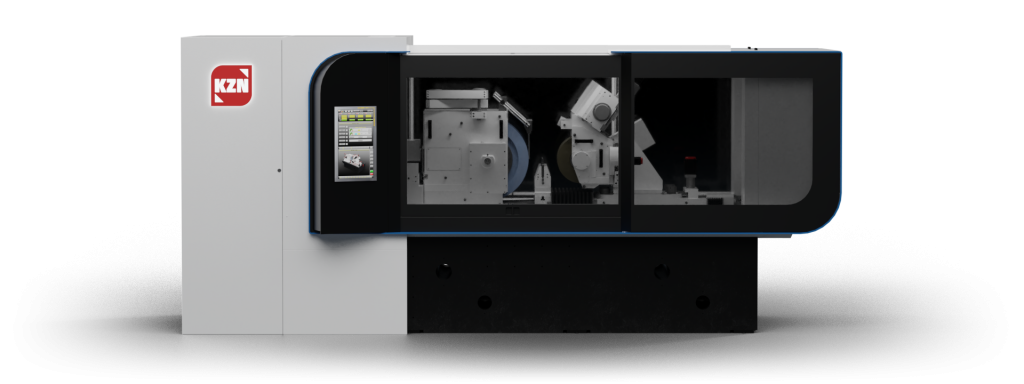

ICGM – Intelligent Centerless Grinding Machine

Project for the development of a grinding machine equipped with Artificial Intelligence.

Initiative implemented within the framework of PRIORITY AXIS I – Strengthening research, development, and innovation Objective Investments in growth and employment Action I.1.b.1.2 – Support for the economic valorization of innovation through experimentation and adoption of innovative solutions in processes, products, and organizational formulas, as well as financing the industrialization of research results.

Beneficiary: Monzesi S.p.A. Benefit Corporation

Project amount € 469.984,81 – Granted support € 234.992,40

Project description: Experimental development project aimed at the development of a validated prototype of a centerless grinding machine equipped with Artificial Intelligence capable of monitoring, correcting, and compensating for process deviations by autonomously adjusting without the assistance of an operator.

Vertical Centerless Grinding Process

Initiative implemented within the framework of PRIORITY AXIS I – Strengthening research, development, and innovation Objective Investments in growth and employment Action I.1.b.1.1 – Support for the purchase of services for the technological, strategic, organizational and commercial innovation of companies.

Beneficiary: Monzesi S.p.A. Benefit Corporation

Project amount € 7.100,00 – Granted support € 5.680,00

Project description: Extension of the industrial invention patent, relating to the conception of an innovative method for minimizing undulations on a workpiece by means of a grinding process, from national to European.